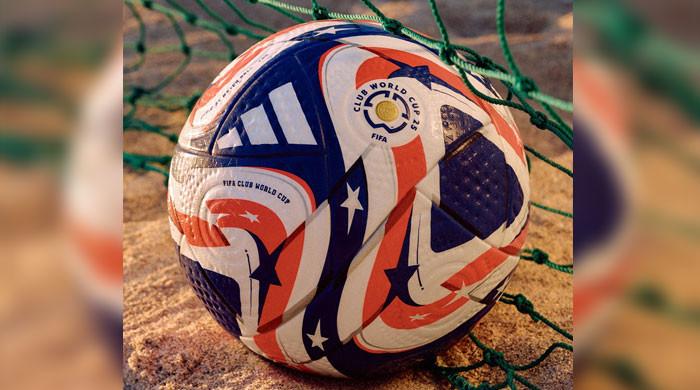

The Fifa Club World Cup 25 Pro Ball, unveiled by Adidas, can be seen in this undated image. — X/@adidasfootball

#Global #football #community #lauds #Pakistanmade #Fifa #ball

The FIFA Club World Cup 25 Pro Ball, Official Matchball, unveiled through Eddie Doss earlier this year, gaining the world’s attention for its amazing stars and strikes design before the start of the mega event in the United States this weekend.

The ball not only captures American pride but also reflects extraordinary performance and engineering, proudly marked with the “Made in Pakistan” label.

Sam Handy, general manager of the football, described the ball as a result of 18 months of severe growth, aimed at creating something “bold, loud, famous and clearly American”.

This combination of aesthetics and functionality exhibits Pakistan’s manufacturing skills.

The 2025 Club World Cup ball also indicates an important move towards sustainability, which is fully developed by eco -friendly materials.

61 polyurethene, 30 % recycled polyester, and 9 % viscose, this new repetition indicates commitment to environmental consciousness methods, while increasing global sports experience.

However, behind its patriotic aesthetic, Pakistan’s manufacturing is evidence of Excellence and high performance engineering, which is proudly developed in the South Asian nation.

It also includes the modern health technology of Adidas. A 20 panel, with a thermal -tied structure, is designed to improve air flow control and enhance the consistency in flight with strategic developed drains.

This is built in Pakistan, where most of the world’s football is manufactured.

The examination at the University of Lofreberg, a leading sports research company in the UK, performed the ball high.

Using both human players and robotic cookers, researchers compared the new Adidas model to the Premier League (Nike Flight), Carabao Cup (Poma and Beta 1), and FA Cup (meter Altimax Pro) balls.

When robot testing showed similar speed and spin in all models, player testing revealed “significant differences”, according to Professor Andy Harland, who oversees the analysis.

The players achieved their fastest strikes and high spin rates with the club World Cup ball – even recorded more than a spin than Nikeball. A player remarked the ball “Terrier hit for professionals”, which suggested that its design meets high -level, precision -based games.

The players observed that the ball was felt stronger and had a small sweet place, demanding more precise contact. However, he appreciated his consistency during the open game, especially for the long, accurate ground passage.

Despite the limited size of the sample, the three players recorded their fastest strikes using the Club World Cup ball. Then a player gave remarks, “It kills Trew for professionals.”

“You had to kill it more clearly,” players noted that the club World Cup ball has a small ‘sweet place’ than others.

On the contrary, robot testing-that Harland “should be closely kept closely” due to “fixed” leg speed and hair placement.

One player said that the players also described this separate feeling while attacking the ball: “Especially the Adidas (Club World Cup) ball, which felt very hard.” Another added, “He has no grip. Because you have small drains, you rotate it more.”

Two players shared a similar decision where it is best: “Maybe in the open game is better. It would be good to kill a long pass, the grassor (a long pass, place on the floor) would be perfect.”

All the balls were manufactured in Pakistan, which mostly produces football in the world. The separate construction of the Club World Cup edition is the reason that players feel such differences when kicking.

According to Eddie Das, the upper -level bowel inside the ball is helpful in maintaining the bladder and forming flight stability. The company is so confident in stability that it offers a two -year -old guarantee.

The ball also includes a motion sensor, which sends data 500 times per second to help semi -automatic office decisions, player tracking and identification of touch points.

This is not the first time the Edidas is high -tech footballs, but the Club World Cup 25 Pro represents a significant evolution from past models such as Furnova from the 2003 Women’s World Cup and the 1994 tournament.

At that time, the balls were handled by hand and made of numerous materials. Since 2004, Eddie Dos has moved to thermal bonding, new panel design now allows extraordinary aerodium precision.

According to Lufferg Testing Lead Ivan Williams, the hair design has been developed at a place where aerodynamics are more than the balance.

He says, “People started to go, ‘Well, they don’t need regular shape anymore. We can do crazy things with the panel.” It has a little corrected, and now we have to make sure that the ball is once again flying, which has made it an investment burden. “

Finally, Eddie Das has broken the current model only from the tradition of re -dying. Club World Cup ball is not just a visual upgrade – this is a technical review made for modern football.

With 63 matches on the horizon, real -world performance of the hair will be under a close check. But so far, preliminary signs show that this Pakistani -made miracle is ready to reach the largest stage.