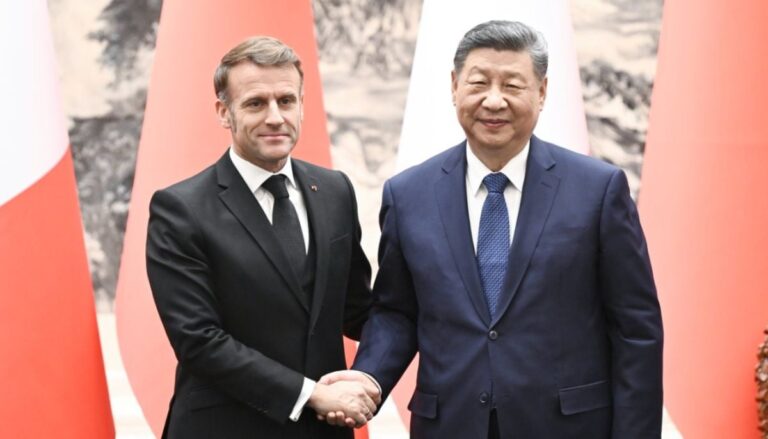

In this photograph women are working at a garment factory. — AFP/File

#Balancing #automation #employment #textile #industry

Lahore: As prices increase and more advanced technology is integrated into the textile sector, the number of workers for specific tasks is usually low. Automation, computerized machinery and efficient production techniques increasing precision, speed and quality by reducing the need for manual labor.

The global textile industry hires more than 70 million workers. India, which ranks fifth in global textile exports, is the highest number of textile workers, 35 million people are employed in the sector. On the contrary, Germany, the world’s second largest textile exporter, hires more than 120,000 workers.

The level of the desired automation varies in different textiles of textile. Basic textile manufacturing (spinning, knitting and knitting) is extremely automatic in most countries, which requires less unit workers per unit. Processing and dyeing are also increasingly automated, but skilled operators are still needed. Garment manufacturing, however, remains labor, because the cutting, sewing and removal task is difficult to automatically, especially in the fast fashion segment.

Bangladesh and after the depreciation of the rupee, Pakistan has the lowest labor costs globally, which is estimated at $ 100- $ 110 per month. This makes the manual process more viable, as automation is not always efficient than cheap wages. Automation is more logical in regions where labor is expensive, such as Europe and China, which is moving itself to automation itself.

A strategic approach is needed to ensure the benefits of productivity without causing widespread unemployment to balance automation by creating job opportunities in Pakistan’s textile sector. Textile industry players should achieve automation according to the product category. Instead of focusing on high -end brands, they should target large -scale markets, which is more labor and creates job opportunities.

On the other hand, high -end technical textiles (such as sports clothing and medical textiles) require automation to achieve precision, quality and high investment profits. The hybrid approach should be adopted, while maintaining large -scale manual sewing, cutting, dyeing and eliminating large -scale stitching to maintain employment.

Instead of imposing automation on a whole scale, Pakistan can adopt semi -automated machines that increase productivity without eliminating jobs. For example, AI -assisted sewing machines can improve speed while human operators are still needed. Similarly, digital printing and dyeing can reduce the loss of water and labor dependence in the traditional process of traditional color. Automatic fabric cutting can be introduced while the manual stitch prevails.

Employment migration and transfer workers must increase the existing workforce to pay for high salary, to minimize technology -related roles. Vietnam successfully promoted its manpower for the manufacture of semi -automatic textiles while increasing wages simultaneously.

Instead of focusing on large -scale production, the government should encourage small -scale garment manufacturers to produce value -added, handmade or customized textiles. Investments should be introduced for companies that invest in workers’ training rather than resort to. The adoption of technology should be subsidized in a way that preserves jobs rather than merely reducing labor costs.

Among the ten textile exporters in the world, five are from Asia – China, Bangladesh, Vietnam, India, Indonesia and Hong Kong – while four are from Europe: Germany, Italy, Turkey and Spain. The United States is the only representative of the United States.

Although most of the global textile and clothing exports (in terms of volume) begin in Asia, European and American exporters generate high exports in each unit. The textile industry is mostly concentrated in Asian countries. China, which is the world’s largest textile exporter, hires 15 million textile workers. Bangladesh’s textile labor market is comprised of more than four million workers, of which women make about 85 % of the workforce.

Indonesia’s textile industry is one of the largest number of people in the world, with more than 2.5 million people employed. Meanwhile, the US textile industry supply chain – from textile fibers to costumes and other sewing products – 110,000 workers in 2021 were employed. In Pakistan, the number of textile workers is 2.5 million.

Germany, which exports more textile products from Bangladesh, India, or Indonesia, has wages that are ten times higher than those countries. However, it works 18 times less than Indonesia, 32 times less than Bangladesh, and 315 times less than India. This discrepancy highlights the power of technology and workers’ performance in the textile sector.